Table of Contents

Introduction

We’ve all heard the phrase, “time is money,” which is especially true for the construction industry. Surveyors frequently deal with daily frustrations related to traditional surveying processes. From the accuracy of data collection to the weighty reliance on paper documents, it feels like they are always fighting an uphill battle.

However, the introduction of laser scanning devices and Building Information Modelling (BIM) is turning things around. Scan to BIM workflow not only provides us with more streamlined workflows, but they also improve our design decisions, particularly in renovation work. In this blog, we will describe some of the normal challenges we grapple with, show how laser scanning is shaking things up, and cover how scanning to BIM is changing surveying for the better in Australia.

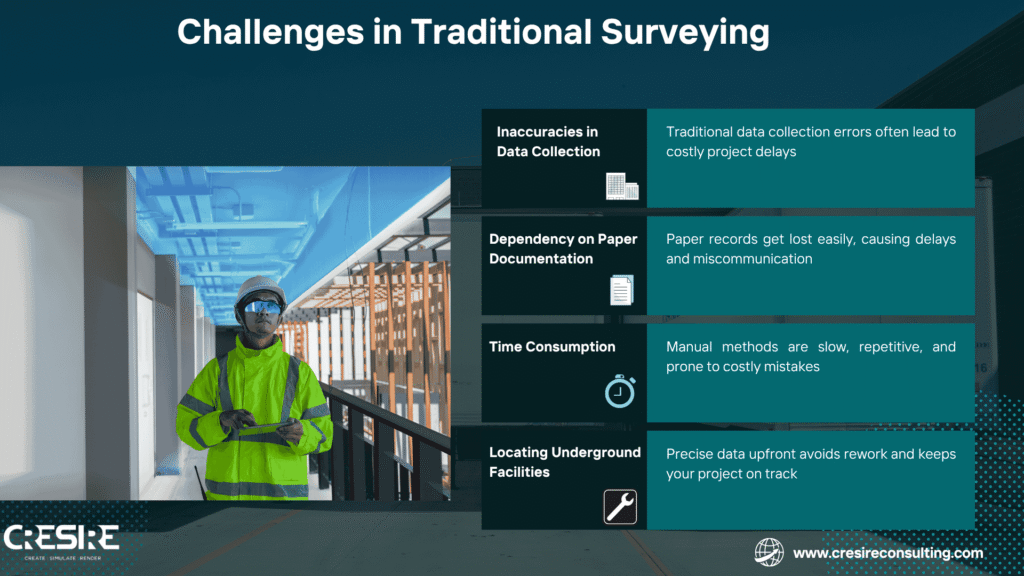

Day-to-Day Challenges of Traditional Surveying Methods

When we reference traditional surveying in australia, most people envision some form of tape measure, large equipment, and most definitely lots of paperwork.

While traditional surveying processes have served us well over time, they come with a series of challenges affecting efficiency and accuracy. Let’s look at some of the typical challenges surveyors face by not using 3D Scan to bim workflow in australia.

- Inaccuracies in Data Collection – For starters, we cannot dismiss the inaccuracies that traditional data collection processes suffer from in Australia. Be these inaccuracies caused by human error or constrained technology, these mistakes end up costing money and as noted above, lead to expensive project delays and budget overruns. In fact, it is common for projects to incur substantial delays and cost overruns as a direct result of bad data. For us, accuracy is critical. There is nothing worse than having to redo something due to a preventable mistake.

- Dependency on Paper Documentation – Next up is our old friend, paper documentation. We all have an idea how simple it is for records to become misplaced, misfiled, or misread. This paper dependence can generate a high degree of miscommunication between project stakeholders, resulting in avoidable delays. And frequently, it makes it harder to access up-to-the-minute data- something we need when we need to make quick, educated decisions.

- Time Consumption and Labor Intensity – Then there’s the sheer time consumption and labour intensity of traditional methods. Manual measurements can be a real drain on our time and energy. It’s not just that the work is repetitive; it’s also that it can lead to human error, which we’ve already established can cause major headaches down the line. We can easily find ourselves mired in these tasks, taking our attention away from more strategic aspects of our projects.

- Locating Underground Utilities – And let’s not forget that the precision of data gathering at this stage is critical, and not finding utilities as they should be is an invite for rework and serious project delay. If not using Point Cloud to bim services, It’s one more level of complication that we must deal with in attempting to see to it that project flow is smooth.

Emergence of Laser Scanning Devices

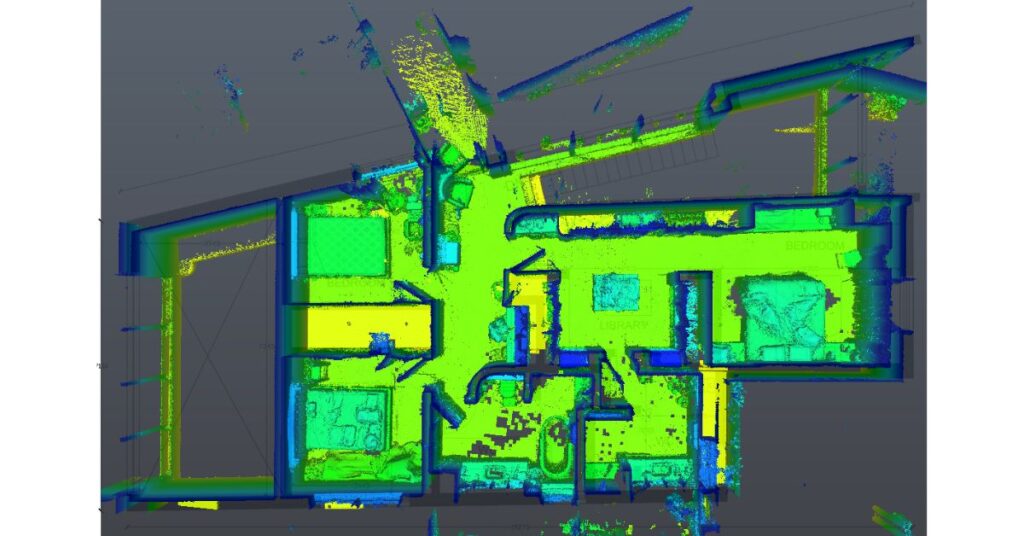

Now think about this: walking into a building, positioning a scanner on a tripod, pushing a couple of buttons and you just took millions of data points at 360 degrees. That’s laser scanning at work. The scanner captures all the design elements around it with LiDAR (Light Detection and Ranging) to create a point cloud to a 3D model of actual space.

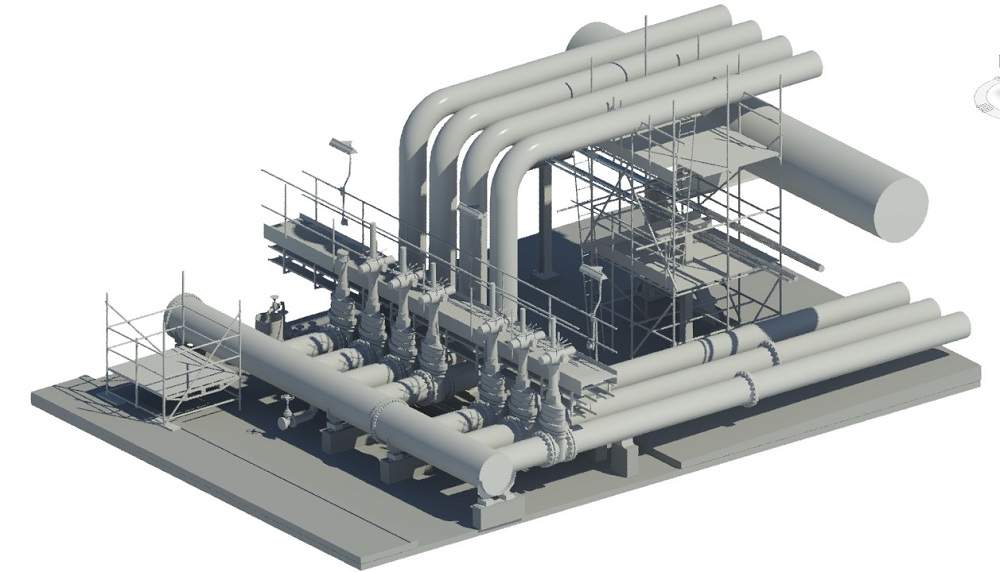

One of the fundamental benefits is the efficiency and accuracy that laser scanning introduces into the Scan to BIM workflow. Traditional techniques will often omit important geometric details, particularly in historic or complex buildings. Laser scanning plugs this loophole, providing millimetre-level accuracy and recording fine architectural detail across decorative mouldings, irregular walls, or vaulted ceilings Also visualisation and communication across project teams.

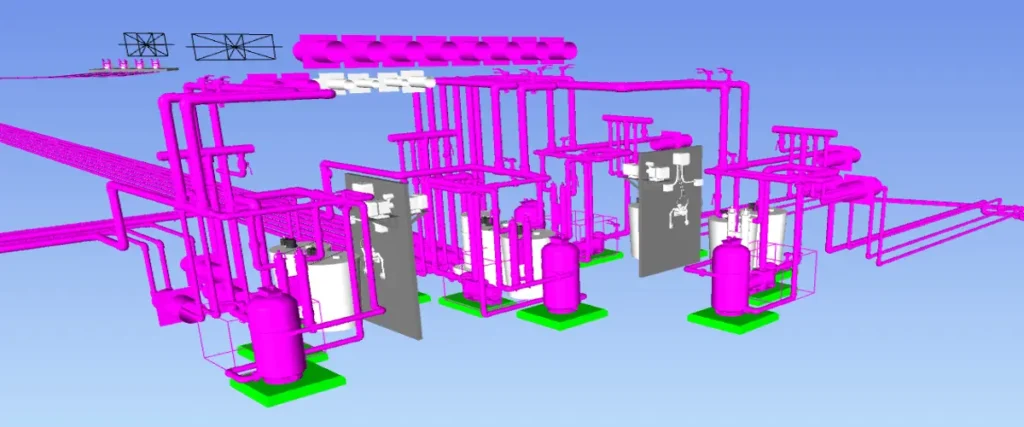

The Scan to BIM information enables clash detection, design coordination, and unambiguous stakeholder comprehension. It also enables integration throughout the project life cycle, and digital models can be kept up to date with physical conditions.

Scanners such as Leica, Trimble, Faro, or even mobile mappers in handheld form are more accessible and easier to use now. You do not have to be an engineer in Silicon Valley anymore. Any average surveyor now can be trained and operational in minutes.

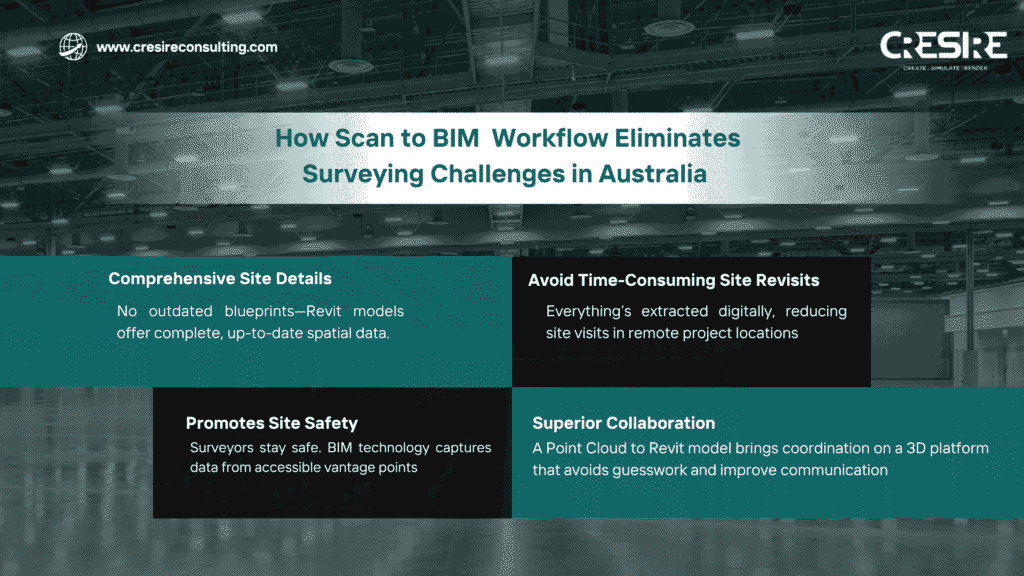

How Scan to BIM modeling Workflow Eliminates Surveying Challenges in Australia?

Traditional survey methods throughout Australia often struggle with aged buildings, lost documentation, distant sites, and the need for rapid and accurate data collection for renovations and maintenance. Traditional methods typically fall short, needing multiple visits, manual measurement and relying on old records including drawings that are often incomplete. But the Scan to BIM workflow is changing that.

Essentially, by introducing 3D laser scanning (LiDAR) to Building Information Models (BIM,) surveyors can understand as-built conditions with precise details in the single visit. The point clouds created by the laser scans feed directly into BIM software such Revit. When high-quality scan data is used, the resulting point cloud to Revit model can achieve millimeter-level accuracy. Thus, removing the common issues like:

- Comprehensive Site Details: No need to rely on outdated blueprints, point cloud to revit models provide complete spatial data of the current structure.

- Avoid Time-consuming site revisits: Once scanned, everything needed can be extracted digitally saving days of repeat travel, especially crucial in remote or industrial areas.

- Promotes Site Safety: Surveyors in Australia will never have to access dangerous or hard to reach confined spaces to get the data. Using Point Cloud to bim services, all hazard data can be captured from limitlessly accessible vantage points.

- Superior Collaboration & Communication: A BIM model that every single stakeholder can access becomes a single source of truth for all parties surveyors’, engineers’, designers’, clients’

Case studies in Queensland water treatment plants showed that Scan to bim workflow in Australia improved project delivery speed, reduced errors, and enhanced operational planning. For instance, the Plant 3D + Revit model enabled simulations, clash detection, and smart P&ID integration, streamlining everything from design upgrades to asset maintenance.

Conclusion

Point cloud to BIM in Australia is the start of a cost-effective long-term asset management strategy, like the greater direction that Australia is embarking upon; a smarter approach to infrastructure. With increasing renovations and digitalising assets, Australian surveyors that have the guts to become early adopters of Scan to BIM workflow will not only be keeping pace, they will be the leaders of the next wave of intelligent infrastructure developments.