Get high-quality Revit family creation services for MEP engineers! Learn the benefits, how it works, and faqs in detail here.

Introduction

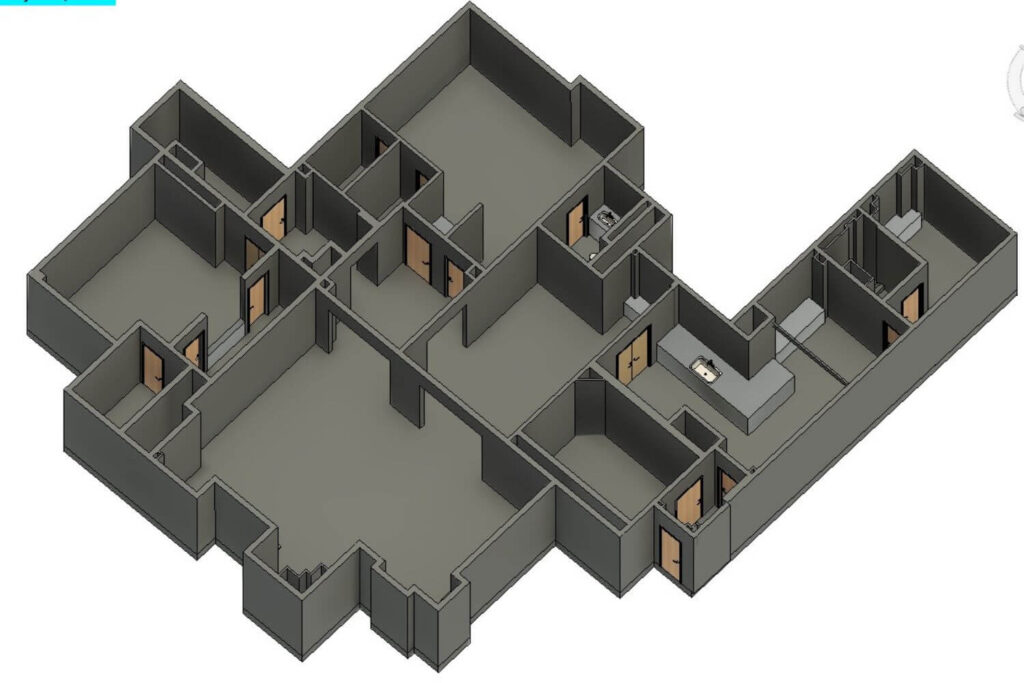

Revit family creation services for MEP engineers are increasingly important for developing precise BIM models.

In today’s construction and design landscape, Revit parametric family development for electrical engineers or specialized Revit families for duct and piping systems is essential for generating accurate bills of quantities and supporting facility management workflows.

MEP engineers and contractors not fully acquainted with 3D modeling or the BIM workflow are often asked by general contractors or project owners to submit detailed MEP BIM models.

In such cases, they are typically faced with two options: either hire an in-house team of BIM engineers or outsource Revit family creation for MEP design firms.

In other scenarios, MEP consultants and engineers may already have a dedicated BIM team, but face resource constraints when it comes to developing specialized Revit families for ductwork, piping systems, and HVAC components. Under these circumstances, outsourcing Revit family creation becomes the preferred and more efficient option.

This article outlines what Revit family creation services for MEP engineers entail, explores the sub-disciplines involved in specialized Revit family development, explains the process of creating LOD 400 Revit families for MEP contractors, and provides insights on how to effectively outsource Revit family creation for MEP projects.

What are Revit Family Creation Services

Revit family creation is the process of developing intelligent, parametric 3D components within Revit. These components, known as families, represent real-world building elements such as ducts, pipes, electrical fixtures, valves, and HVAC units.

What sets them apart is their parametric behavior – meaning they can adapt in shape, size, material, and function based on input parameters defined during creation.

Key Types of Revit Families

- System Families: Built-in elements like walls, ducts, or floors.

- Loadable Families: Custom, reusable components such as valves, air terminals, or pumps.

- In-Place Families: Project-specific elements used in unique conditions.

A Revit family can include both the geometric representation, and the associated data needed for design, analysis, and coordination. This makes them essential for accurate and consistent Building Information Modeling (BIM).

For MEP Engineers, Revit family creation plays a vital role in enabling them to model and coordinate mechanical, electrical, and plumbing systems in a virtual environment.

Rather than drawing 2D symbols or generic 3D blocks, MEP professionals use custom Revit families to simulate real-world components that include technical specifications like voltage, flow rate, or insulation type.

How Revit Family Creation Services help MEP Engineers

- Ensure accurate space planning and clash-free routing of services

- Develop precise bill of quantities (BOQs)

- Maintain design uniformity across large, complex BIM models

- Generate coordinated construction documents directly from the model

Sub-Disciplines of MEP Family Creation in Revit

Revit Family Creation Services for MEP Engineers covers three subdisciplines that are Mechanical, Electrical, and Plumbing.

Each of the sub-domains involves developing custom, parametric 3D components that help engineers design and coordinate accurate, data-rich BIM models. Let’s step by step understand each of the disciplines and sub-disciplines below:

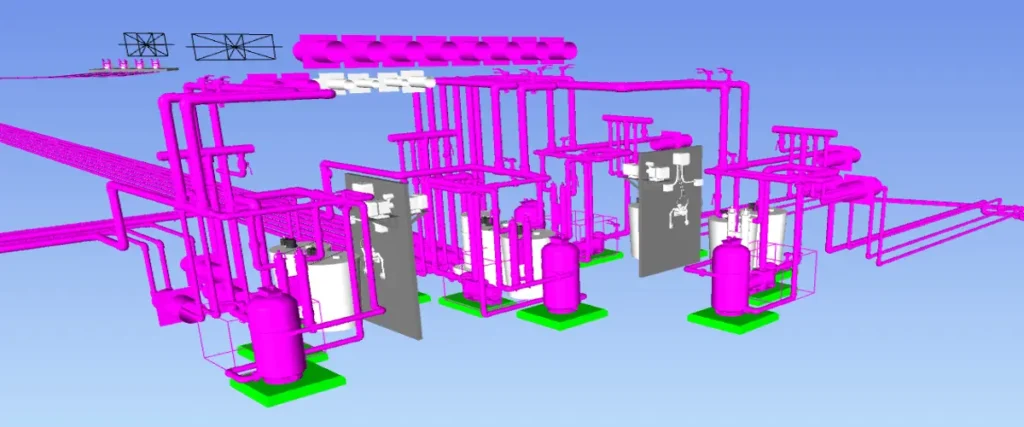

1. Mechanical Revit Family Creation

In mechanical design, engineers use Revit families to model components like HVAC units, VAV boxes, chillers, exhaust fans, and duct fittings. These families respond to real-world parameters such as airflow rate, pressure drop, and equipment dimensions.

By creating custom HVAC Revit families for BIM coordination, mechanical teams can improve system layout, run load simulations, and avoid clashes during construction.

2. Electrical Revit Family Creation

Revit parametric family development for electrical engineers relies on tailored families for light fixtures, switchgear, conduits, cable trays, and distribution boards. These families include parameters like voltage, circuit ID, power load, and mounting type.

With accurate Revit family creation for electrical systems, designers streamline panel schedules, circuit layouts, and on-site installation.

3. Plumbing Revit Family Creation

Plumbing design teams develop families for pumps, valves, sanitary fixtures, water heaters, and pipe accessories. The plumbing fixture Revit family creation carries data for flow rate, pressure rating, pipe connection size, and material type.

Engineers use Revit plumbing family development for BIM projects to coordinate piping layouts, support hydraulic calculations, and meet compliance standards.

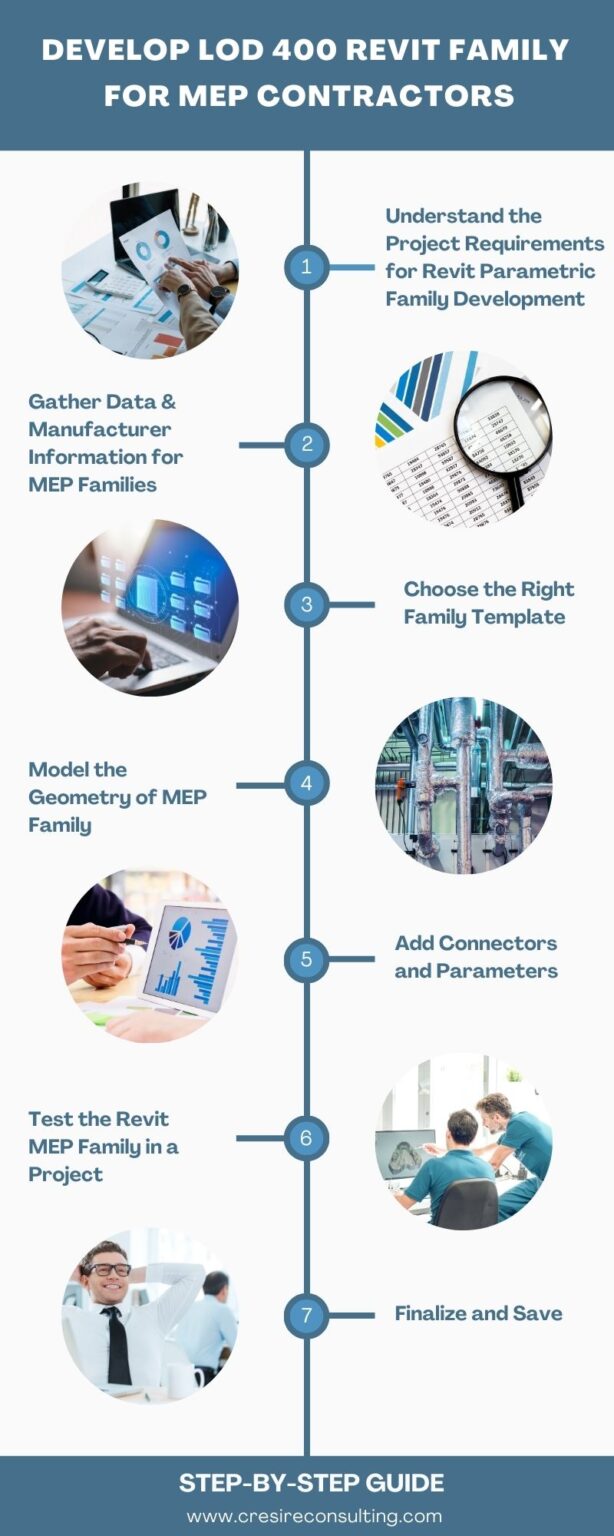

Step-by-Step Guide: Developing an LOD 400 Revit Family for MEP Contractors

Creating a LOD 400 Revit family for MEP contractors may sound complex at first, but once you break it down into manageable steps, it’s much easier to handle.

At LOD 400, the model is highly detailed, providing accurate geometry and data for fabrication, installation, and coordination. Let’s walk through the process, step by step, for Revit Family Creation Services for MEP Engineers:

Step 1: Understand the Project Requirements for Revit Parametric Family Development

Before you dive into the modeling process, it’s crucial to have a clear understanding of exactly what’s required.

Start by reviewing the project’s BIM Execution Plan (BEP). This document will provide valuable insight into the specific LOD requirements, especially for LOD 400, where the focus is on creating a family that is highly detailed and ready for real-world installation.

Understanding these requirements early on ensures that the Revit family creation process is aligned with project goals and that your model will meet the necessary standards for fabrication, installation, and coordination.

The more thoroughly you review the BEP, the better prepared you’ll be to create a family that fits seamlessly into the overall BIM workflow, minimizing the chance of revisions later on.

Step 2: Gather Data and Manufacturer Information for MEP Families

For developing Revit family creation services for MEP engineers, such as pumps, valves, HVAC units, or electrical panels, gathering the right data is absolutely crucial. This step forms the foundation of your entire modeling process.

Make sure to collect comprehensive technical sheets, manufacturer specifications, and accurate dimensions for each component. Pay close attention to details like connection sizes, flow rates, voltage ratings, pressure specifications, and material types.

These pieces of information are essential because they will directly influence the accuracy and functionality of your MEP Revit family.

By using precise manufacturer data, you ensure that your families represent real-world components in terms of performance and compatibility. This attention to detail also helps maintain the integrity of your BIM workflow, enabling smooth integration into the larger project model.

Ultimately, gathering and utilizing the correct data will not only make the modeling process more efficient but also ensure that the families are accurate, adaptable, and ready to be used across various stages of your project, from design coordination to installation.

Step 3: Choose the Right Family Template

Once you have your data, open Revit and pick the right family template– make sure it matches the type of MEP component you’re creating.

Revit has specific templates for mechanical, plumbing, and electrical families. These templates set up the structure, so you don’t have to start from scratch.

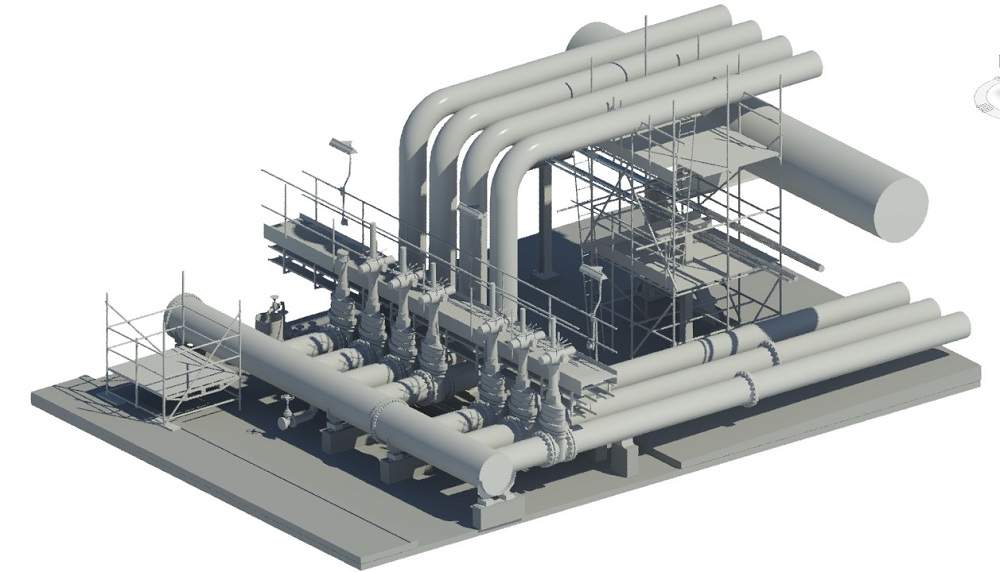

Step 4: Model the Geometry of MEP Family

Using the manufacturer’s data as your foundation, start modeling the component in 3D with precision and care. When developing a LOD 400 Revit family for MEP systems, the geometry must be highly detailed. This includes connectors, mounting features, support brackets, and even necessary clearances for servicing and maintenance access.

Every small detail matters at this level. The objective is to create a realistic, data-rich MEP Revit family that mirrors the actual product as closely as possible. This ensures seamless integration into the overall BIM model and supports fabrication-level accuracy.

Whether you are modeling an HVAC unit, a pump, or an electrical panel, capturing its physical and functional characteristics is essential for effective BIM coordination and downstream use in construction and facility management.

Step 5: Add Connectors and Parameters

Now it’s time to move into one of the most important parts of MEP Revit family creation—adding connectors. This step ensures that your component can interact correctly within the BIM model.

Add connectors for systems such as ducts, pipes, cable trays, or electrical circuits, depending on the type of family you’re building.

Next, define critical parameters that bring your model to life. These include values like voltage, flow rate, pressure drop, and material type. These parameters not only make your family intelligent and functional but also support automation in your project workflows.

They are essential for generating accurate schedules, applying consistent tags, and performing reliable quantity takeoffs in BIM projects.

Whether you are creating a custom HVAC family, an electrical panel, or a plumbing fixture, assigning the right parameters and connectors ensures the family works seamlessly in design coordination, fabrication planning, and facility maintenance.

This step bridges the gap between a static 3D model and a fully functional, BIM-compliant MEP family.

Step 6: Test the Revit MEP Family in a Project

Now, load the newly created Revit family into a sample project environment and integrate it with your existing MEP systems.

This is where you evaluate how the component performs in a real-world setup. Carefully test its placement – make sure it fits correctly within the model, aligns with nearby elements, and maintains proper system connections.

Check whether the family interacts smoothly with other components in your BIM environment. Look for any geometry conflicts, connectivity errors, or parameter mismatches. If you’re working with HVAC, electrical, or plumbing families, it is vital to ensure all connectors are behaving as expected and data flows correctly between systems.

This testing phase is a critical quality control step in the Revit MEP family creation process. It helps you confirm that the family is not only technically accurate but also practical for actual design coordination, fabrication, or installation use.

Identifying and resolving issues at this stage will save significant time during later project phases and ensure seamless performance across your BIM workflow.

Step 7: Finalize and Save

Once everything looks good and you have thoroughly tested the family, it’s time to lock in your parameters and finalize the model.

Clean up the family by removing any unnecessary elements or excess data that might clutter the file. Ensure that the model is streamlined, efficient, and ready for future use.

Next, give the family a clear, consistent name that follows your team’s naming conventions. This is important for maintaining organization and ease of reference, especially as your library of MEP Revit families grows.

Finally, save the family in a well-organized directory and document its version, specifications, and intended usage. This step ensures that your team can easily find and use the family in future projects.

Proper documentation also helps maintain version control and traceability, making collaboration smoother and preventing any confusion later on. By following these steps, you’ll ensure that your Revit MEP family is ready to be seamlessly integrated into your future designs

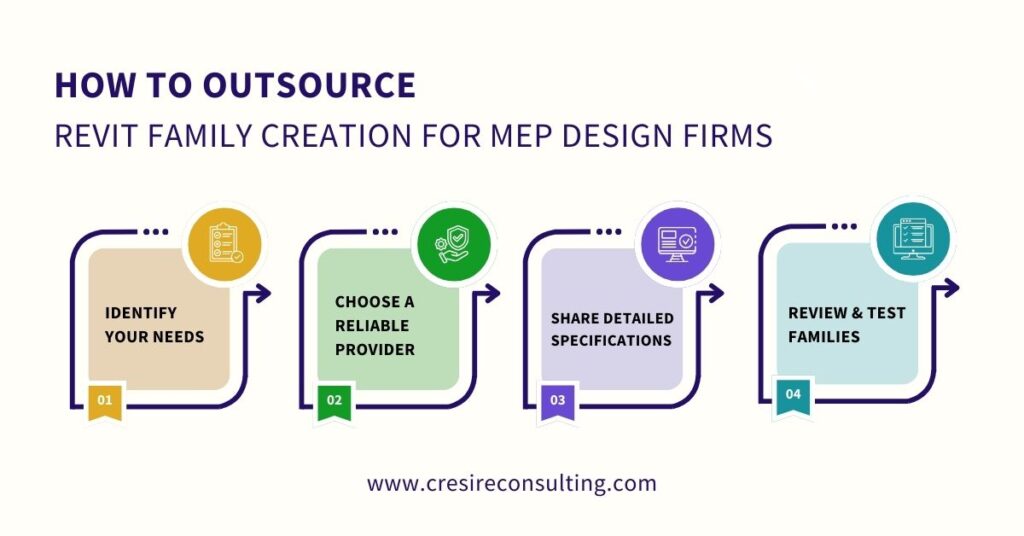

How to Outsource Revit Family Creation for MEP Design Firms

Revit MEP family outsourcing services for efficiency is a good way to enhance project delivery without overburdening your in-house team.

By outsourcing Revit family creation tasks, firms can leverage specialized expertise, save time, and ensure high-quality, data-rich BIM-compliant Revit family creation for facility management that aligns with project requirements.

1. Identify Your Needs

Before you start the outsourcing process, take the time to clearly define what you need. Are you looking for custom HVAC Revit families, detailed electrical fixtures, or specialized plumbing components?

Pinpointing exactly what you expect from the deliverables is key. Think about the types of systems involved, the level of detail required, and how these families will be used within your BIM workflow.

It’s also important to determine the LOD requirements- for example, whether you need LOD 300 for design coordination or LOD 400 for fabrication-level detail. Having this clarity upfront not only helps you stay organized but also makes it much easier to communicate your expectations to the outsourcing partner.

The more specific you are, the better the outcome will be, saving you time, reducing revisions, and ensuring the families integrate smoothly into your Revit models.

2. Choose a Reliable Provider

Look for a BIM outsourcing partner with solid, hands-on experience in MEP design and Revit family creation. It’s important to work with a team that not only understands the technical aspects but also has a proven track record of delivering for projects similar to yours.

Review their portfolio to see if they’ve worked on MEP systems that match your scale, complexity, and industry requirements. Also, make sure they’re well-versed in industry standards, BIM protocols, and the latest Revit software capabilities.

Beyond that, choose a team that genuinely understands Revit parametric family creation- this means they should be able to create smart, flexible families that adjust to different project conditions without losing accuracy.

The right outsourcing partner will focus on detail, ensuring every Revit family is built with reliable data, correct classifications, and real-world functionality.

That level of precision can make a big difference in how smoothly your BIM models come together during design coordination and construction planning.

3. Share Detailed Specifications

Make sure you provide the outsourcing partner with clear and detailed documentation. This should include everything from manufacturer specifications and technical drawings to your project’s specific BIM requirements.

The more context and information you can share, the better equipped the partner will be to deliver accurate, high-quality results.

It’s essential to communicate your expectations clearly – don’t assume they’ll guess what you need. Define the intended use of each Revit family, the required parameters, and any naming conventions or modeling standards your team follows.

When the guidelines are well-structured and easy to follow, it reduces back-and-forth, speeds up delivery, and ensures the families are fully compatible with your existing BIM models.

In the end, thoughtful preparation and open communication go a long way in making sure the Revit families not only meet your project goals but also support a smooth workflow for your entire design team.

4. Review and Test Families

Once the Revit families are delivered, take the time to conduct a thorough review before moving forward. Load each family into a test Revit project and check how well it fits within your design environment.

Look closely at the geometry, ensure all connectors are placed correctly, and verify that the parameters and data reflect what you originally requested.

Functionality is just as important as appearance, so test how the families behave when connected to your MEP systems. Do they work properly in schedules? Are they easy to tag and filter? Can they be adjusted without breaking the model? These checks help you catch any issues early, so you can request updates if needed.

The goal is to make sure the families integrate smoothly into your workflow and support accurate coordination and documentation across your project. A careful review now saves a lot of reworks later.

10 Benefits of Specialized Revit Family Creation Services for MEP Engineers

Revit is a popular Building Information Modeling (BIM) software used by MEP (Mechanical, Electrical, and Plumbing) engineers to design and manage building systems.

One of the most important features of Revit is its ability to create and manage families, which are the building blocks of any Revit model.

1. Customization

Specialized Revit family creation services can create families that are tailored to the specific needs of MEP engineers. This allows for greater customization and flexibility in the design process.

2. Efficiency

By having custom families created for their specific needs, MEP engineers can save time and increase productivity by streamlining their design process.

3. Accuracy

Custom families created by specialized Revit family creation services are created with precision and accuracy, ensuring that the final model is as accurate as possible.

4. Consistency

Custom families created by specialized Revit family creation services are created with precision and accuracy, ensuring that the final model is as accurate as possible.

5. Optimization

Custom families can be created to optimize the performance of building systems, resulting in more energy-efficient designs and cost savings.

6. Collaboration

Specialized Revit family creation services can facilitate collaboration between MEP engineers and other stakeholders by creating families that can be shared and reused across multiple projects.

7. Expertise

Specialized Revit family creation services have a deep understanding of the Revit software and can provide expert advice and guidance to MEP engineers.

8. Quality

Custom families created by specialized Revit family creation services are of high quality and meet industry standards.

9. Cost-Effective

Specialized Revit MEP family creation services can help MEP engineers save money by creating families that can be reused across multiple projects.

10. Innovation

Specialized Revit MEP family creation services can help MEP engineers stay up-to-date with the latest technologies and industry trends by providing innovative solutions and ideas for their designs.

Also Read, 3 Benefits of Revit Family Creation For Lighting Manufacture Firm

Conclusion

Revit Family Creation Services for MEP engineers are no longer a luxury- they’re a necessity in today’s BIM-driven construction landscape.

Whether you are dealing with Revit parametric family development for electrical engineers, specialized duct and piping systems, or plumbing fixture modeling, the demand for accurate, data-rich, and LOD-specific Revit families is greater than ever.

BIM-compliant Revit family creation for facility management serves as the digital backbone of MEP BIM models, offering engineers the precision they need for design coordination, quantity take-offs, fabrication, and facility management.

For firms juggling complex projects or facing internal resource limitations, outsourcing becomes a practical strategy, especially when the Revit families required go beyond standard libraries and demand custom-built, LOD 400-ready components.

However, success depends on choosing the right partner, setting clear expectations, and maintaining strong communication throughout the process.

Get FREE Quote

For BIM Services for Your Project

Our Recent Projects on BIM Services

Related Posts

Share Via

Tags

Devashish Sharma

Devashish is Founder/Director at Cresire where he leads BIM services. He holds a bachelor’s degree in Civil Engineering from the University of Sheffield and an MSc in Construction Project Management from The University of the West of England. His vision behind CRESIRE is to provide BIM services, adhering to best practices and procedures, to global customers, helping customers to save extensive production costs and overruns.