Table of Contents

Introduction

There’s a reason prefabrication and modular construction are gaining serious traction across healthcare, commercial, and infrastructure projects. They promise something the industry has been chasing for decades: predictability.

But prefabrication only works when everything fits. Not “almost fits.” Not “we’ll adjust it on site.” It has to fit the first time.

That’s where MEP Shop Drawing Services move from being simple documentation to becoming a production tool.

If architectural drawings explain what a building should look like, and design MEP drawings explain how systems should work, shop drawings explain exactly how those systems will be built, installed, and connected in the real world.

Why Prefabrication Depends on MEP Shop Drawings

In traditional construction, small inconsistencies can be solved on-site. A pipe route shifts slightly. A support gets adjusted. A cable tray gets raised by 20 mm.

In prefabrication, those adjustments become expensive problems.

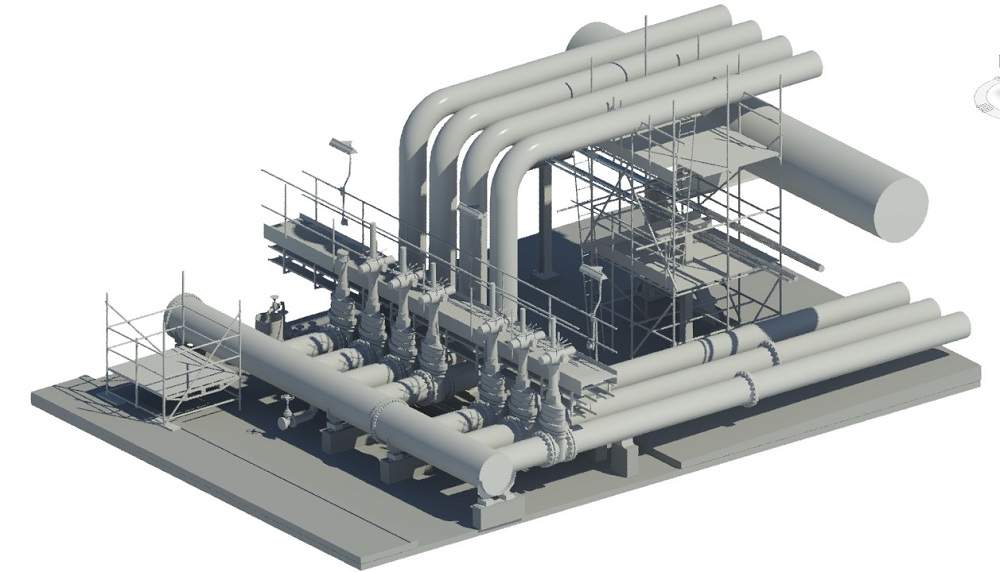

Prefabricated racks, corridor modules, plant skids, and service modules are built off-site. By the time they reach the site, they need to slot into place without modification. That level of precision comes directly from high-quality MEP detailed drawings services.

Without accurate shop drawings, prefabrication turns into rework. And rework defeats the entire purpose of modular construction.

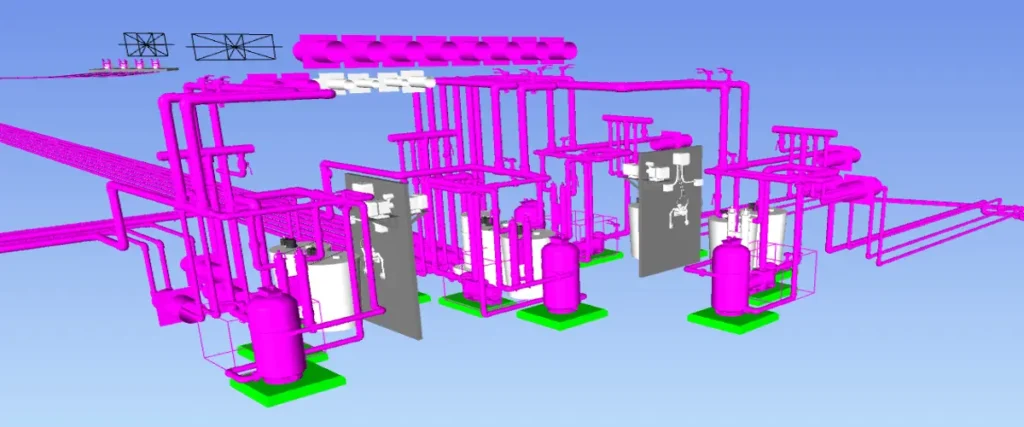

From Design Intent to Buildable Reality

Design-stage MEP layouts focus on performance and compliance. Shop drawings focus on buildability.

This is where the level of detail increases significantly. Shop drawings include:

- Exact pipe and duct routing

- Support and hanger locations

- Clearance zones for installation and maintenance

- Connection details between systems

- Fabrication spool breakdowns

This level of detail is especially critical in projects such as MEP drawings for hospitals, where system density is high, and the tolerance for installation error is very low.

In hospital projects, a small routing mistake isn’t just a coordination issue. It can affect medical gas systems, infection control requirements, or equipment access.

The Growing Link Between MEP Shop Drawings and Prefabrication Workflows

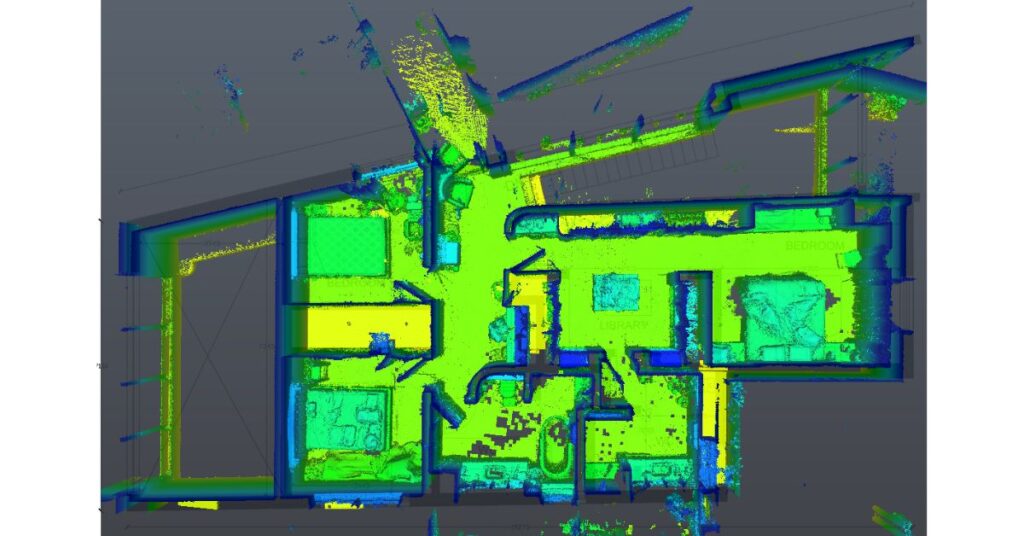

In modular construction environments, shop drawings are often used directly on fabrication floors.

Fabrication teams rely on:

– Spool drawings

– Assembly layouts

– Fabrication cut lists

– Installation sequence references

This is why many contractors now request both native CAD files and MEP drawing PDF sets. CAD files support fabrication workflows. PDF sets support field teams and site supervisors who need quick reference without navigating complex models.

How MEP Diagram Drafting Supports Early Planning

Before shop drawings reach fabrication-level detail, MEP diagram drafting plays an important role in system planning. These diagrams help teams:

– Understand system flow logic

– Validate equipment connections

– Plan installation sequencing

– Review redundancy systems

In prefabrication projects, diagram-level clarity helps prevent costly redesign later, especially when modules are already in production.

Why Healthcare and Data-Critical Facilities Depend Heavily on MEP Shop Drawings?

Healthcare projects are the clearest example of why MEP shop drawings matter. Hospitals include:

Dense ceiling service zones

- Critical redundancy systems

- Strict compliance requirements

- Complex equipment connections

High-quality MEP drawings for hospitals must account for all of this while still allowing maintenance access and future upgrades. In these projects, shop drawings often go through multiple review layers, including contractor, consultant, client engineering teams, and sometimes medical equipment vendors.

Reducing Site Risk Through Detail

One of the biggest advantages of detailed shop drawings is risk reduction. When systems are coordinated and fabricated correctly:

- Fewer site modifications are needed

- Material waste is reduced

- Installation is faster

- Quality control improves

For modular construction, this consistency is essential. Modules are often installed in tight schedules, sometimes overnight or during limited shutdown windows.

The Human Side of MEP Shop Drawing Production

Despite automation and modeling tools improving every year, shop drawings still rely heavily on human experience.

Understanding how systems are installed in real site conditions matters just as much as software skills. Knowing where installers need access. Knowing where tolerance stacking can cause problems. Knowing which details need extra clarity.

Good MEP detailed drawings services don’t just produce drawings. They produce installation-ready information.

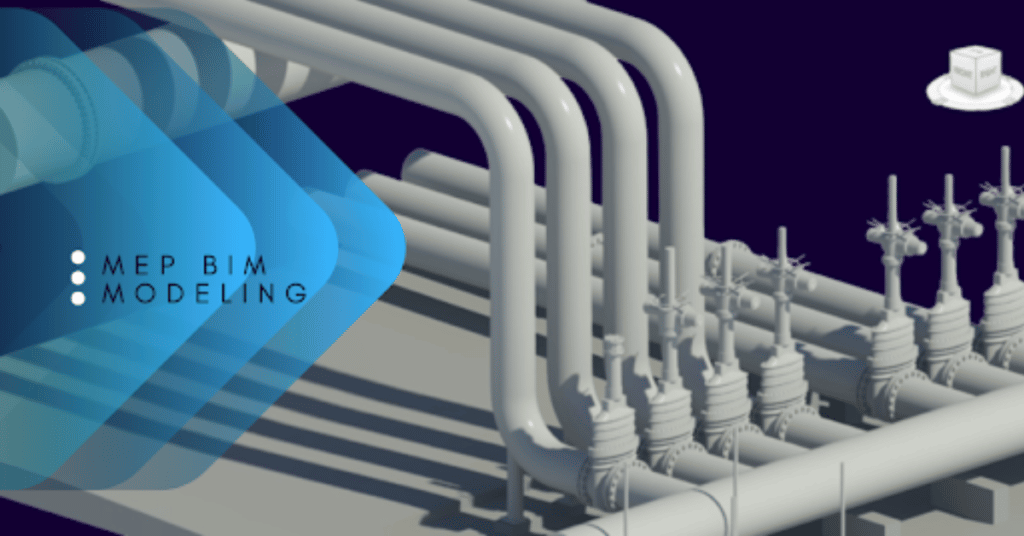

Where the Industry Is Moving

Prefabrication is becoming standard practice in:

– Healthcare construction

– Data centers

– Airports

– Commercial high-rise developments

– Pharmaceutical facilities

As this shift continues, MEP shop drawings are becoming less of a downstream deliverable and more of an early-stage production document. More teams are now integrating shop drawing development alongside BIM coordination rather than treating it as a final step.

Final Thoughts

Prefabrication and modular construction are changing how buildings are delivered. But the success of these methods still depends on one simple thing, accuracy.

MEP Shop Drawings bridge the gap between design and physical construction. They help ensure systems are not only designed correctly, but built correctly the first time.

In projects where time, quality, and coordination matter, which is most modern construction, detailed MEP shop drawings are no longer optional. They are part of the production process itself.

Also read: The Growing Trend of BIM Modeling Services for MEP

About Us – Cresire Consulting

At Cresire Consulting, we are committed to delivering high-quality BIM, CAD, and engineering support services tailored to the evolving needs of the AEC industry. With a client-focused approach and a passion for precision, we help architects, engineers, and contractors streamline their workflows and achieve project success with confidence.

We believe in building long-term business relationships with reputable clients by consistently delivering accuracy, reliability, and complete customer satisfaction. Our team works closely with every client to understand project requirements and provide customized, cost-effective solutions that add measurable value.

We invite you to explore our services and discover how Cresire Consulting can support your next project. Feel free to reach out through our contact page to discuss your requirements, or email us directly at enquiry@cresireconsulting.com.

Frequently Asked Questions (FAQs)

1. What are MEP shop drawing services in prefabrication projects?

MEP shop drawing services provide detailed, installation-ready drawings that guide fabrication and modular construction. Unlike design drawings, shop drawings define exact routing, supports, connections, and dimensions required for off-site production and on-site installation.

2. Why are MEP shop drawings critical for modular construction?

In modular construction, systems are built off-site and must fit perfectly during installation. High-quality MEP fabrication drawings ensure precision, reduce rework, and prevent costly on-site modifications, making prefabrication efficient and predictable.

3. How do MEP drafting services differ from design-stage MEP drawings?

MEP drafting services focus on converting design intent into buildable details. While design drawings show system performance and layout concepts, shop drawings include fabrication spools, hanger locations, clearance zones, and installation sequencing.

4. How do MEP shop drawings reduce risk in healthcare projects?

Healthcare facilities require dense coordination and zero tolerance for errors. Accurate MEP drawings for hospitals ensure that medical gas systems, HVAC, electrical, and plumbing networks are installed correctly while maintaining compliance and access for maintenance.

5. Can MEP shop drawings support both BIM and field teams?

Yes. Many contractors request native CAD files for fabrication and BIM coordination, along with PDF drawing sets for site teams. This dual format ensures seamless workflow from digital modeling to physical installation.

6. When should MEP shop drawing development begin?

In modern projects, especially prefabrication-heavy builds, MEP shop drawing services are integrated early during BIM coordination. Early involvement improves clash detection, sequencing, and overall constructability.

7. How do MEP detailed drawings improve installation speed?

By eliminating ambiguity, detailed shop drawings reduce site modifications, material waste, and installation errors. This accelerates module placement and ensures consistent quality control across large projects.

8. Why should contractors outsource MEP shop drawing services?

Outsourcing to experienced providers ensures technical accuracy, compliance, and production-ready documentation. It allows contractors to focus on execution while receiving reliable, installation-ready drawings.

Devashish is Founder/Director at Cresire where he leads BIM services. He holds a bachelor’s degree in Civil Engineering from the University of Sheffield and an MSc in Construction Project Management from The University of the West of England. His vision behind CRESIRE is to provide BIM services, adhering to best practices and procedures, to global customers, helping customers to save extensive production costs and overruns.